- Acronym Guide

- AAM

- ABS

- AC

- ACAS

- ADS-B

- AFAC

- AGL

- AI

- AIM

- ALS

- AM

- AMA

- ANSP

- AOI

- APPI

- AUV

- AUVSI

- ARPAS-UK

- ASTM

- ATC

- BVLOS

- CAA

- CAAC

- CAB

- CAP

- CASA

- CATT

- CBO

- CBR

- CBRN

- CDMA

- CDR

- CFI

- CFR

- CIR

- COA

- COMINT

- CORS

- COTP

- COTR

- CPTED

- CV

- C2

- DAA

- DAS

- DEM

- DFI

- DFS

- DGCA

- DHS

- DOD

- DPA

- DPEs

- DRG

- DRO

- DSM

- DSMX

- DSP

- DSSS

- DTM

- EASA

- EFT

- EO

- EOD

- EO/IR

- ELINT

- EMI

- ESC

- EVLOS

- eVTOLs

- FAA

- FCC

- FCS

- FHSS

- FICCI

- FLIR

- FOB

- FOV

- FPS

- FPV

- GBDAA

- GCP

- GCS

- GDPR

- GML

- GNSS

- GPS

- GSD

- GVC

- HDR

- HOGE

- IACRA

- ICAO

- ICS

- IMU

- INS

- IR

- ISA

- ISR

- ITU

- JARUS

- LAAMS

- LAANC

- LAATM

- LAI

- LAS

- LBA

- LIDAR

- LOS

- LSALT

- MAC

- MAVLink

- MLIT

- MMS

- MSL

- MTOM

- NDAA

- NCSL

- NFZ

- NIST

- NMEA

- NOTAM

- NPA

- NPRM

- NTIA

- OBIA

- OEM

- OFDM

- OGI

- OOP

- PAS

- PASM

- PAV

- PCV

- PdM

- PEC

- PIC

- PID

- PIPL

- PLD

- PM

- PN

- PPK

- PPS

- PSM

- PTZ

- PWM

- UAM

- UAOP

- UAS

- UASTM

- UAV

- UCAVs

- UHD

- UHF

- USV

- UTM

- RAIM

- RCC

- RCS

- RFI

- ReOC

- RePL

- RMS

- ROI

- RPAS

- RPC

- RTH

- RTN

- RTK

- SaR

- SAR

- SARP

- SBAS

- S.Bus

- SBIR

- SEDENA

- SfM

- SFOC

- SIGINT

- SLAM

- SMS

- SOP

- SORA

- STANAG

- STTR

- STK

- sUAS

- TCAS

- TCCA

- TFR

- TIN

- TLM

- TOF

- TP

- TPS

- TSA

- VHF

- VLOS

- VTOL

Drone Acronyms

What is PdM (Predictive Maintenance) ?

By

Jacob StonerTable Of Contents

Definition

PdM stands for Predictive Maintenance. It is a proactive approach to maintaining equipment by using data analytics, machine learning, and sensor data to predict when maintenance is required before a failure occurs. By monitoring the condition of machinery in real-time and analyzing historical data, PdM helps prevent unexpected equipment failures and extends the lifespan of assets by identifying maintenance needs before breakdowns happen.

Usage

Predictive maintenance is widely used across industries like manufacturing, aerospace, and logistics, including in the drone industry. By using sensors to collect data on a drone’s components, such as motors, batteries, and sensors, operators can analyze trends and identify when parts are likely to fail. This allows for timely repairs, reducing downtime and enhancing operational efficiency.

Relevance to the Industry

In the drone industry, PdM is particularly important for ensuring the safety and reliability of drones, especially in commercial applications where drones are used for critical tasks like deliveries, inspections, or emergency services. Predictive maintenance minimizes the risk of unexpected failures, which can lead to costly downtime or even accidents.

How Does Predictive Maintenance (PdM) Work?

Data Collection:

- Sensors and Monitoring Devices:

- Real-Time Monitoring: PdM relies on sensors installed on machinery or drones to continuously collect data about the condition and performance of critical components. These sensors monitor parameters such as temperature, vibration, pressure, battery levels, and other operational factors. In drones, for example, sensors may monitor the battery’s charge cycles, rotor performance, and motor temperature.

- Data Transmission: The collected data is transmitted to a central system or cloud-based platform where it is stored and analyzed. This data is recorded over time to track trends and detect anomalies that may indicate the onset of equipment failure.

- Condition-Based Data:

- Machine Health Monitoring: The system tracks the health of various components, looking for signs of wear, degradation, or malfunction. For drones, PdM might track motor efficiency, rotor vibration, or battery voltage irregularities, which are early indicators of potential issues.

- Wear and Tear Analysis: By analyzing the degradation of components over time, PdM systems can estimate the remaining useful life of individual parts, allowing operators to perform maintenance before the part fails entirely.

Data Analysis and Machine Learning:

- Predictive Algorithms:

- Pattern Recognition: Predictive maintenance systems use machine learning algorithms to analyze the data collected from sensors. These algorithms identify patterns that correlate with equipment failure. For instance, an increase in motor vibration combined with rising temperatures might indicate a motor bearing is wearing out.

- Failure Predictions: The system uses historical data and real-time sensor readings to predict when a specific component is likely to fail. This allows operators to schedule maintenance at a convenient time, avoiding unplanned downtime.

- Thresholds and Alerts:

- Predefined Limits: In many PdM systems, predefined thresholds are set for each monitored parameter. If a parameter exceeds its threshold (e.g., excessive motor temperature), the system generates an alert. This provides early warning to operators so they can address the issue before it escalates into a failure.

- Automated Alerts: PdM systems can automatically notify operators via alerts or notifications, enabling timely responses. For drones, this might mean grounding a drone for inspection before a flight if the data suggests that a failure could occur.

Maintenance Scheduling and Optimization:

- Proactive Maintenance:

- Timely Repairs: PdM allows maintenance to be performed only when necessary, based on the actual condition of components, rather than relying on scheduled or reactive maintenance. This minimizes unnecessary downtime and reduces maintenance costs.

- Just-in-Time Parts Replacement: The system can predict when a component is nearing the end of its useful life, allowing operators to order replacement parts just in time for repairs. This avoids overstocking parts and reduces inventory costs.

- Integration with Operations:

- Fleet Management Systems: In the case of drones, PdM systems can be integrated into broader fleet management systems. This ensures that maintenance is seamlessly coordinated with operational schedules, minimizing the impact on flight missions.

- Maintenance Logs: PdM platforms often integrate with maintenance management software, automatically updating maintenance logs and tracking the performance of components over time.

Feedback and Continuous Improvement:

- Learning from Data:

- Continuous Improvement: The system continuously learns from new data, refining its predictive capabilities over time. This means that PdM systems get more accurate as they gather more data and are able to predict failures earlier and more precisely.

- Customization: Predictive maintenance systems can be customized to specific operational environments. For example, in the drone industry, PdM algorithms can be adjusted to account for different operational conditions, such as flight altitude, environmental factors, and drone model-specific data.

- Operational Efficiency:

- Reducing Unplanned Downtime: By anticipating when maintenance is required, PdM helps operators avoid unexpected equipment failures that can cause significant downtime and disrupt operations.

- Extending Asset Lifespan: Regularly maintaining components based on their actual condition, rather than waiting for a failure to occur, extends the lifespan of machinery and reduces the need for costly replacements.

By combining real-time monitoring, data analysis, and predictive algorithms, Predictive Maintenance (PdM) offers a proactive approach to equipment management. It ensures drones and other machinery remain operational and safe while reducing costs and preventing unexpected failures.

Example in Use

“By implementing predictive maintenance, the drone operator was able to schedule repairs for the motor before it failed during a critical inspection flight, saving time and preventing costly delays.”

Frequently Asked Questions about PdM (Predictive Maintenance)

1. How does PdM work?

Answer: Predictive maintenance works by:

- Data Collection: Sensors attached to the equipment continuously monitor various parameters such as temperature, vibration, pressure, and voltage. In drones, this may include monitoring the battery’s health, rotor performance, or GPS signal strength.

- Data Analysis: The collected data is then analyzed using machine learning algorithms to detect patterns or anomalies that indicate potential equipment failure. For example, if the temperature of a drone’s motor consistently exceeds a certain threshold, it could be an early sign of wear and tear.

- Predicting Failures: Based on historical data and real-time monitoring, predictive maintenance systems can predict when a component is likely to fail. This allows operators to perform maintenance before the failure occurs, preventing unexpected downtime and reducing repair costs.

2. What are the benefits of using PdM?

Answer: The benefits of predictive maintenance include:

- Reduced Downtime: By predicting failures before they happen, maintenance can be scheduled during non-operational hours, minimizing downtime.

- Lower Maintenance Costs: PdM reduces the need for frequent, unnecessary maintenance and prevents costly emergency repairs by addressing issues before they become critical.

- Improved Asset Lifespan: Regular monitoring and timely maintenance extend the lifespan of machinery and equipment by preventing premature failure.

- Increased Safety: In industries like drone operations, predictive maintenance helps prevent in-flight failures that could lead to accidents, protecting both the equipment and public safety.

3. How is PdM applied in the drone industry?

Answer: In the drone industry, predictive maintenance is applied by:

- Monitoring Components: Sensors on drones collect data about critical components such as motors, propellers, batteries, and sensors. This data is analyzed to detect signs of wear, degradation, or imminent failure.

- Analyzing Flight Data: By analyzing flight data and historical performance, drone operators can predict when specific parts are likely to fail and schedule maintenance accordingly.

- Reducing Operational Risk: PdM helps reduce the risk of drone failures during flight, especially in commercial or mission-critical operations like deliveries, inspections, or search and rescue.

For examples of these acronyms visit our Industries page.

As the CEO of Flyeye.io, Jacob Stoner spearheads the company's operations with his extensive expertise in the drone industry. He is a licensed commercial drone operator in Canada, where he frequently conducts drone inspections. Jacob is a highly respected figure within his local drone community, where he indulges his passion for videography during his leisure time. Above all, Jacob's keen interest lies in the potential societal impact of drone technology advancements.

Pros

Cons

You may like

What is TLM (Telemetry) & How Does it Work?

What is PTZ (Pan-Tilt-Zoom) & How Does it Work?

What is PAS (Passive Acoustic Sensor) & How Does it Work?

What is OGI (Optical Gas Imaging) & How Does it Work?

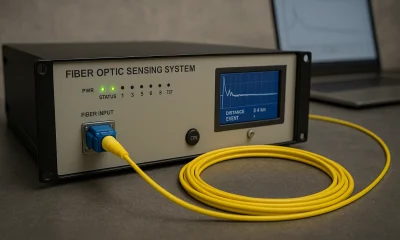

What is DAS (Distributed Acoustic Sensing)?

What is CFI (Certified Flight Instructor) & How Does it Work?